Supply Chain Risk Management

Increased Risk

Change and uncertainty are breeding grounds for risk and the timing of Brexit alongside the global pandemic has seen the opportunity for risk to increase significantly.

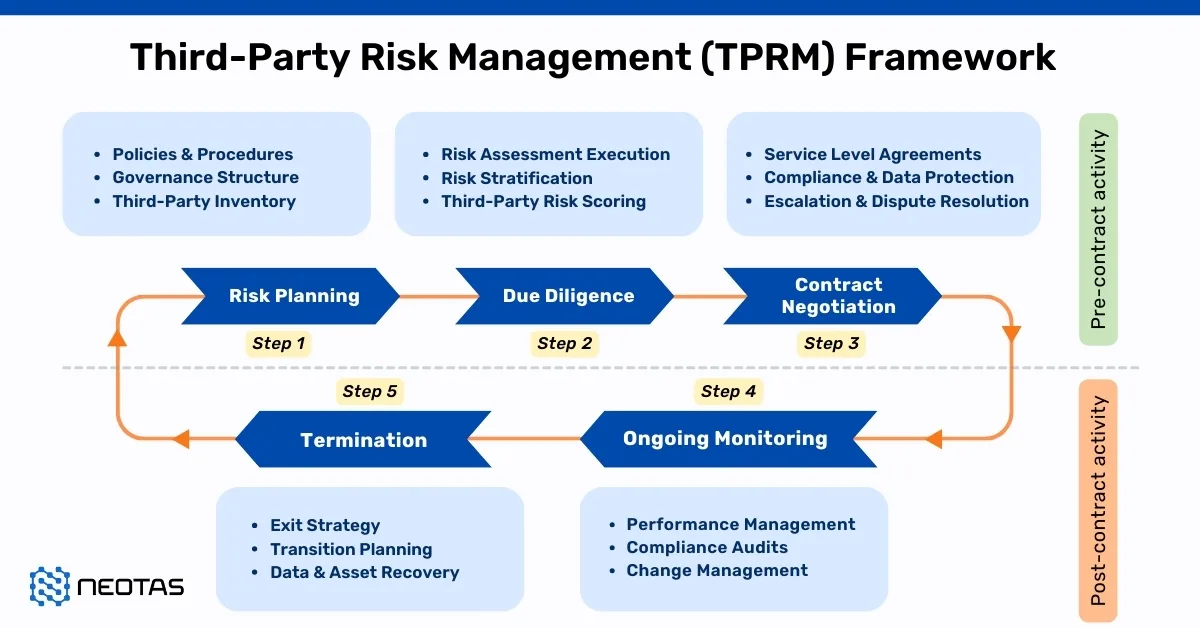

The risk management lifecycle is familiar to many of us:

- Risk identification

- Risk assessment

- Risk mitigation

But what about when the risks, and the dangers and implications associated with them, evolve? What about when well established procedures and risk management protocols are turned on their head by unprecedented global events?

KPMG predicted a “tsunami of fraud” in 2021 as the financial world catches up with the implications of the coronavirus pandemic. Our reports have signalled an increase in fraudulent activity so far this year and it shows no signs of slowing down yet.

Locking down a globalised world has brought with it intense challenges for risk management. Global supply chains have come under immense pressure as they deal with changing localised restrictions, the societal impact of the health crisis and the need for many businesses to adapt to survive.

So how do we solve the problem of increased risk? With uncertainty looking here to stay, the solution may be to supplement your supply chain risk management practices with a more agile approach.

Why Have We Seen Supply Chain Risk Increase?

Through both the pandemic and the changing regulations of Brexit, businesses have been forced to adapt in almost every way. Supply chains have been rocked by unforeseen vulnerabilities, often left exposed by the new pressures we have found ourselves under.

The globalised nature of many multi-tier supply chains has seen these challenges exacerbated from the top down. A single product could now have hundreds or even thousands of suppliers contributing to its delivery, with risk increasing at every stage.

Travel restrictions have contributed to increased risk. Supply chain risk management becomes an even more difficult task when face-to-face assessments are limited and we become reliant on remote reporting and approval systems.

The typical lag in reporting and the uncertainty of the past 18 months means that it can also be difficult to trust financial data on the surface. Without further inspection, how can you trust that a supplier’s most recent statements are sound, when the pre-pandemic period may no longer be applicable and the during-pandemic period was so unprecedented?

Lastly, social media also has a part to play in reputational risk. Managing reputational damage can play a significant role in the overall health of a business and while financial data can lag, social media’s impact can be swiftly felt and unforgiving. Reputations can be tarnished by association so while it may not be your fault directly – it can still be your problem.

“You can insure against the failure of a customer, but how would you deal with the failure of a key supplier?” – Deloitte

Supply Chain ESG Risk

With an increased focus on ESG, comes greater scrutiny for the supply chain. The general public has never been more interested in knowing where their products came from, who made them and what impact their production had on the environment. The wrong decision could be catastrophic for industry.

In a modern multi-tier supply chain, the firm at the top of the chain remains at least partly responsible for the sustainability and societal impact of the suppliers at the bottom – at least in the eyes of the public. The larger the chain, the more difficult it can become to identify risks – particularly when subcontractors are introduced and when the only method of reporting is remote self-reporting.

We recently discussed the increased risks that ESG-specific investing can face, including reputational issues and corporate greenwashing, with FinTech expert Brendan Bradley.

Restrictions Highlight Self-Reporting Shortcomings

The self-reporting model has always relied on honesty and integrity from companies but with increased pressure brought by the pandemic, businesses have been forced to adapt. Are firms likely to divulge information that could harm their reputations? Brendan Bradley thinks possibly not:

“Are firms likely to divulge information that could harm their reputations? I think there’s a grey area there with respect to what they will report and how much that’s actually being fully audited. If these assessments are being reduced to box-ticking and that’s never audited, you’re reliant on complete honesty from organisations whose number one interest will always be self-preservation.”

While self-reporting models were previously audited and punctuated by announced and unannounced site visits, travel restrictions have rendered those a thing of the past. As such, an independent, data driven, flexible auditing solution is required to help lower risks.

An ideal reporting model would no longer rely on self-reporting alone to assess the risks and credibility of a supplier and would also report data closer to real-time.

Time To Stay Compliant

The disruptions to supply chains have brought with them increased risk of non-compliance. The need to improvise and adapt brought by the pandemic has led to increased likelihood of non-compliance amongst suppliers, as chains came under pressure to continue operating under heavy restrictions.

Personnel Today recently reported on a huge surge in umbrella companies being used to abuse the UK tax system, with suppliers taking advantage of reduced taxation loopholes. The potential impact for associated companies includes regulatory action, as well as the reputational damage of non-compliance within your supply chain.

An independent audit of suppliers, building a clear risk profile using public data can help highlight any issues in transparency and ensure the chain remains compliant.

Identifying The Weak Link

“Your supply chain is only as strong as its weakest link” – Deloitte

While tried and trusted supply chain risk management procedures continue to be effective, now more than ever it’s crucial to be agile in our response to risk. It’s critical that businesses can establish a clear risk profile for each of their suppliers, highlighting vulnerabilities and assessing a wide range of financial and non-financial factors.

Are your supply chain screening procedures up to date? Are they robust enough to identify modern risks including cyber risk, risks associated with the pandemic or modern slavery?

Identify the risk factors most appropriate to your business. Design a risk model that will allow you to identify which suppliers are the most important and which are the most vulnerable. It’s about making sure you have the tools, expertise and techniques to gain a high level of understanding of your key suppliers.

Using Open Source Intelligence To Lower Supply Chain Risk

The role that open source intelligence (OSINT) can play in reducing supply chain risk is clear. Using OSINT we can monitor risks much closer to real-time, highlighting potentially damaging events or actions that occur outside of the regular reporting period.

Through OSINT, we are able to map supplier networks and analyse non-financial risks including those linked to adverse media, customer feedback, ESG and more. Adopting an enhanced, AI-driven model to supplement existing checks allows for deeper insights to inform your supply chain risk management strategy.

Technology like Neotas’ proprietary advanced machine learning technology is capable of processing vast quantities of relevant risk data, lowering the reliance on the self-reporting model. Our enhanced risk & compliance solutions aren’t limited by global jurisdictions and harness natural language processing to analyse data in over 200 languages.

The time to adapt traditional supply chain risk management practices is now. Using OSINT powered EDD, businesses can harness publicly available data to help lower supply risks. Get in touch with our team today to discuss your supply chain risk management practices and how we can lower your risks.

New Whitepaper and Checklist

New Whitepaper and Checklist