Supply Chain Risk Management

Identifying Supply Chain Risks with a structured approach to supply-chain risk management. In this article we will explore the Strategies, Challenges, and Best Practices to Assess and Mitigate Supplier Risk.

What is supply chain risk management (SCRM)?

Supply Chain Risk Management (SCRM) is a systematic approach to identifying, assessing, managing, and mitigating risks within the supply chain. This process encompasses the entire lifespan of a product, from the initial sourcing of materials to the delivery of the final product to the consumer. The primary objective of SCRM is to ensure the smooth and efficient operation of the supply chain, minimising disruptions and protecting against potential losses.

- Fundamentals of Supply Chain Risk Management: Supply Chain Risk Management (SCRM) is the strategic orchestration of methods to identify, evaluate, and mitigate risks along the supply chain. Its aim is to assure continuity and efficiency in business operations, safeguarding against interruptions and potential losses.

- Risk Identification: This stage involves recognising various risks like logistical challenges, supplier issues, natural disasters, political upheavals, and cyber threats.

- Risk Assessment: Post-identification, risks are quantified based on their likelihood and potential impact, which helps in prioritising them.

- Risk Mitigation Techniques: Developing strategies to either reduce the probability of risk occurrence or to diminish its impact is a critical aspect of SCRM.

- Diversification: This involves strategies such as using multiple suppliers or logistics routes to reduce dependence on a single entity.

- Resilient Infrastructure: Investing in robust infrastructure and technology to enhance adaptability and response to disruptions.

- Inventory Management: Maintaining optimal inventory levels to manage supply and demand fluctuations.

- Advanced Analytics: Utilising predictive analytics and AI for proactive risk management and decision-making.

- Monitoring and Reviewing: Continuous monitoring and regular reviews of the supply chain help in early detection and response to emerging risks.

- Real-Time Data Analysis: Leveraging technology for real-time data analysis and monitoring.

- Periodic Review Process: Regularly updating risk management strategies to align with evolving supply chain dynamics and external environments.

- Collaboration and Communication: Effective SCRM is underpinned by collaborative efforts and clear communication across all levels of the supply chain.

- Internal Collaboration: Cross-departmental collaboration within an organisation for cohesive risk management.

- Partner Engagement: Close cooperation with suppliers, logistics providers, and customers for a united approach to managing risks.

- Challenges and Adaptation: Supply Chain Risk Management must continuously evolve to address new challenges such as globalisation, technological advancements, and changing market conditions.

- Data Quality and Integration: Ensuring high-quality, integrated data is critical for effective risk assessment and decision-making.

- Adapting to Globalisation: Navigating complexities in global supply chains, including varied regulations and geopolitical risks.

- Technological Evolution: Staying abreast with technological advancements and their implications on supply chain operations.

Effective Supply Chain Risk Management is crucial not just for mitigating risks, but also for enhancing overall business resilience and sustainability. It involves a continuous process of identifying risks, implementing mitigation strategies, monitoring outcomes, and adapting to new challenges. Collaboration, both internal and external, is key to successful SCRM, as is the utilisation of advanced technologies for risk assessment and management.

A structured approach to Supply Chain Risk Management

A structured approach to Supply Chain Risk Management involves a comprehensive and proactive strategy to identify and address potential disruptions. This approach can be broadly divided into two categories: managing known risks and managing unknown risks.

Managing Known Supply Chain Risks

- Risk Mitigation Strategies: Implementing practices to lessen the impact or likelihood of known risks. This includes diversifying suppliers, improving quality control, and enhancing operational efficiency.

- Contingency Planning: Developing detailed plans for responding to various risk scenarios, ensuring that the business can continue operations with minimal disruption.

- Stakeholder Collaboration: Working closely with suppliers, customers, and other stakeholders to jointly manage risks. This includes transparent communication and shared responsibility for risk management.

Managing Unknown Supply Chain Risks

- Adaptive Risk Management Practices: Establishing flexible processes that can adapt to new and emerging risks. This requires ongoing risk assessment and the agility to modify strategies as needed.

- Scenario Planning and Preparedness: Engaging in extensive scenario analysis to prepare for potential future risks, even those that are currently unknown or seem unlikely. This includes regular reviews and updates of risk management plans to ensure they remain relevant and effective.

A structured approach to supply-chain risk management requires a balance of proactively addressing known risks and being adaptable to manage unknown risks. This includes implementing risk mitigation strategies, planning for contingencies, fostering stakeholder collaboration, and continually adapting risk management practices to address emerging challenges.

Supply Chain Exposures – What It Means to a Risk Manager

Supply chain exposures refer to the vulnerabilities or potential points of failure within a supply chain that could lead to disruptions or losses. These exposures can arise from a variety of sources and can have significant impacts on operational efficiency, cost, and the overall performance of a business. Understanding and managing these exposures is a critical component of Supply Chain Risk Management (SCRM). Key types of supply chain exposures include:

- Supplier Reliability and Concentration Risks:

- Dependency on a limited number of suppliers or a single supplier can lead to significant disruptions if those suppliers face issues.

- Supplier solvency, especially in cases where critical components or services are sourced from financially unstable suppliers.

- Geopolitical and Regulatory Risks:

- Changes in trade policies, tariffs, and import/export regulations can affect supply chain costs and efficiency.

- Political instability or conflict in regions where suppliers or logistics routes are located.

- Logistical and Transportation Risks:

- Disruptions in transportation networks due to natural disasters, strikes, or infrastructure failures.

- Increasing costs of logistics and challenges in capacity management.

- Quality and Compliance Risks:

- Issues related to the quality of materials or components received from suppliers.

- Non-compliance with regulatory standards or industry-specific requirements can lead to legal repercussions and reputational damage.

- Market and Demand Risks:

- Fluctuations in market demand impacting inventory management and production planning.

- Rapid changes in consumer preferences or technological advancements leading to product obsolescence.

- Environmental and Natural Disaster Risks:

- Exposure to natural disasters such as floods, earthquakes, or extreme weather conditions that can disrupt supply chains.

- Environmental risks and sustainability concerns, including the impact of supply chain operations on the environment.

- Cybersecurity and Information Technology Risks:

- Vulnerabilities in IT systems that could lead to data breaches, loss of intellectual property, or disruptions in automated supply chain processes.

- Reliance on digital technologies making supply chains susceptible to cyber-attacks and system failures.

- Financial and Currency Risks:

- Fluctuations in currency exchange rates affecting the costs of imported materials or components.

- Credit risks associated with customers or suppliers affecting cash flows.

- Human Capital Risks:

- Skills shortages or labour disputes impacting supply chain operations.

- Health and safety incidents or pandemic outbreaks affecting workforce availability.

- Reputational Risks:

- Issues in the supply chain leading to negative public perception or loss of customer trust.

- Association with suppliers or processes that are ethically or socially controversial.

Effective management of these exposures requires a comprehensive approach, including thorough risk assessment, development of mitigation strategies, continuous monitoring, and adaptation to evolving risks. This often involves leveraging advanced technologies for better visibility, diversifying supply sources, enhancing supplier relationships, and integrating robust business continuity and contingency planning.

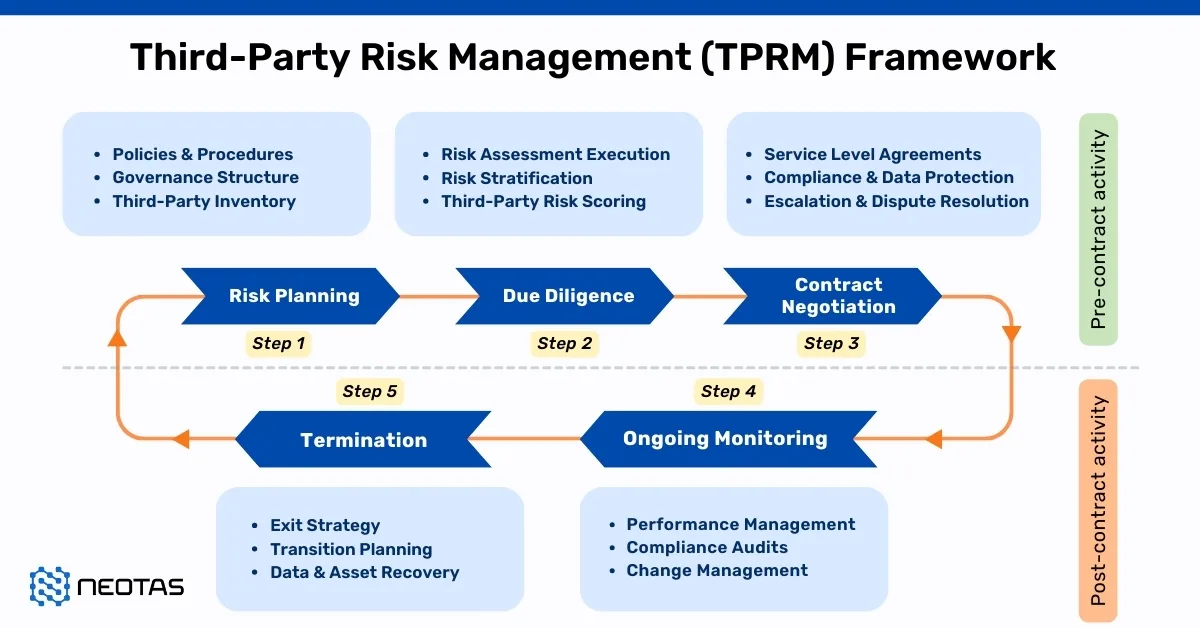

Risk Management Process for a Supply Chain

The Risk Management Process for a Supply Chain is a critical and structured approach designed to identify, assess, mitigate, and continuously monitor potential risks that can disrupt supply chain operations.

This process encompasses various stages, starting with the identification of potential internal and external risks, ranging from supplier issues to geopolitical factors.

It then involves a thorough analysis of these risks, assessing their likelihood and potential impact on the supply chain.

Based on this analysis, appropriate mitigation strategies are developed, aiming to reduce vulnerability and enhance resilience.

Continuous monitoring ensures timely detection and response to new risks, while effective communication among all stakeholders maintains transparency and collaborative risk handling. Regular review and updates of the risk management strategies are crucial, accommodating changes in the business environment and the evolving nature of risks.

This comprehensive approach is essential for maintaining the efficiency, reliability, and sustainability of supply chain operations in an increasingly complex and interconnected global business landscape.

| Step | Description | Key Activities |

|---|---|---|

| 1. Risk Identification | Identifying potential risks that could impact the supply chain | – Mapping the supply chain – Conducting risk assessments – Gathering intelligence from various sources |

| 2. Risk Analysis | Evaluating the identified risks | – Determining the likelihood of each risk – Assessing the potential impact – Prioritising the risks |

| 3. Risk Mitigation | Developing strategies to reduce or manage risks | – Implementing risk control measures – Diversifying suppliers and routes – Enhancing process resilience |

| 4. Risk Monitoring | Continuously overseeing risk factors | – Regularly reviewing and updating risk assessments – Tracking key risk indicators – Using technology for real-time monitoring |

| 5. Risk Communication | Sharing risk information with stakeholders | – Regular updates to all stakeholders – Transparent reporting on risk status and management efforts – Collaborating for joint risk mitigation |

| 6. Risk Review and Update | Re-evaluating and adjusting risk management strategies | – Periodic review of the entire risk management process – Adapting to changes in the supply chain or external environment – Updating strategies and practices as needed |

Extent of Supply Chain Disruption

Supply chain disruptions can vary in extent, ranging from minor delays to major crises that impact the entire supply chain. The severity depends on factors like the nature of the event, geographical spread, duration, and the supply chain’s preparedness and resilience. Disruptions can lead to operational halts, financial losses, diminished customer trust, and long-term reputational damage.

Benefits of Supply Chain Risk Management

Supply Chain Risk Management is a strategic implementation that can lead to significant enhancements in overall business performance and sustainability.

Here’s a closer look at the benefits of Supply Chain Risk Management:

- Enhanced Resilience: One of the primary benefits of Supply Chain Risk Management is the increased resilience of the supply chain. By identifying potential risks and implementing mitigation strategies, businesses can prepare for and quickly respond to various disruptions. This resilience is vital in maintaining operations under adverse conditions, thereby safeguarding against operational halts and the resulting financial losses.

- Cost Efficiency: Supply Chain Risk Management contributes significantly to cost management. By proactively managing risks, companies can avoid the high costs associated with supply chain disruptions, such as expedited shipping, production delays, and lost sales. Efficient risk management also helps in optimising inventory levels, reducing waste, and improving the allocation of resources.

- Competitive Advantage: A robust Supply Chain Risk Management system can provide a substantial competitive edge. In an era where supply chain disruptions are common, the ability to maintain consistent supply chain operations is a significant market differentiator. Companies with resilient supply chains are more reliable partners and often preferred by customers who prioritise dependable service and product availability.

- Improved Compliance and Governance: With increasing regulations and compliance standards globally, Supply Chain Risk Management helps businesses in adhering to these requirements. It ensures compliance with international trade laws, environmental regulations, and industry standards, thereby reducing legal risks and potential penalties.

- Customer Satisfaction and Trust: Consistent and reliable supply chain operations lead to improved customer satisfaction. By ensuring that products are available when needed and maintaining quality standards, businesses can build and maintain trust with their customers, which is critical for long-term relationships and customer loyalty.

- Risk Visibility and Better Decision Making: Effective Supply Chain Risk Management provides clear visibility into potential risks, enabling informed decision-making. With advanced analytics and risk assessment tools, businesses can anticipate potential issues and make strategic decisions to navigate these risks effectively.

- Agility and Flexibility: Supply Chain Risk Management enables businesses to be more agile and flexible. In the face of changing market conditions, geopolitical tensions, or sudden demand shifts, companies with a well-structured SCRM process can adapt quickly, pivot operations as needed, and seize new opportunities while mitigating potential downsides.

- Supply Chain Collaboration and Partnerships: Supply Chain Risk Management fosters closer collaboration with suppliers and partners. By working together to manage risks, companies can strengthen their relationships with key supply chain partners, leading to improved communication, better understanding of mutual challenges, and joint development of risk mitigation strategies.

- Reputational Enhancement: In today’s world, a company’s reputation is closely tied to its supply chain performance. Effective Supply Chain Risk Management helps in maintaining a positive brand image by minimising incidents that could lead to negative publicity, such as product recalls or compliance violations.

- Long-Term Sustainability: Finally, Supply Chain Risk Management contributes to the long-term sustainability of a business. By ensuring that the supply chain is robust, compliant, and adaptable, companies are better positioned to thrive in an ever-changing global business environment, securing their future in the market.

Supply Chain Risk Management is not just a defensive tactic but a strategic business enabler. It goes beyond mitigating risks, extending into areas of operational efficiency, customer satisfaction, competitive advantage, and long-term sustainability.

Identifying Supply Chain Risks

What are some risks that may affect supply chain operations?

In the intricate and multifaceted supply chain operations, understanding and managing risks is paramount to ensuring stability and continuity. These risks, stemming from both internal and external factors, can considerably influence the efficacy of supply chain processes.

External Supply Chain Risks

External risks, originating outside the organisation, are often less predictable and necessitate substantial resources for effective management.

- Natural Disasters: Events such as floods, earthquakes, and severe weather conditions can severely disrupt transportation and supply routes.

- Geopolitical Instability: Political unrest, changes in government policies, and cross-border tensions can lead to unpredictability in trade agreements and supply chain continuity.

- Economic Fluctuations: Market volatility can impact pricing, demand, and availability of goods and services, influencing supply chain operations.

- Regulatory Changes: Alterations in laws and regulations, including those related to trade, environmental standards, and customs procedures, can have a substantial impact on supply chain practices.

Internal Supply Chain Risks

These risks are inherent within the organisation but are generally more controllable.

- Production Bottlenecks: Challenges in manufacturing processes or workflow disruptions can lead to delays and inefficiencies.

- Quality Control Issues: Failures in maintaining product standards can result in recalls, reputational damage, and financial losses.

- Inventory Management Problems: Inaccurate forecasting and suboptimal inventory levels can lead to excess stock or stockouts.

- Workforce Disruptions: Issues such as labour strikes, skill shortages, or health crises can impact productivity and operational efficiency.

Mitigating Supply Chain Risks

Recognising the full spectrum of potential supply chain risks is crucial for proactive management. Employing supply chain risk assessment tools and robust analytics can help identify and monitor these risks. Technologies, including IoT and advanced data analytics, provide visibility and insights into the supply chain, enabling better risk management. For instance, predictive analytics can transform historical data into actionable insights, while APIs can facilitate real-time updates and comprehensive views of supply chain operations by integrating data from various sources.

Comprehensive understanding and strategic management of both internal and external risks are vital for a resilient supply chain. Employing advanced technologies and robust risk assessment methodologies not only aids in identifying potential disruptions but also facilitates the development of effective strategies to mitigate these risks. This approach ensures that businesses are better prepared to handle uncertainties, maintaining operational efficiency and safeguarding against potential losses.

Supply Chain Risk Management Strategies

Supply Chain Risk Management (SCRM) strategies are essential in today’s global and technologically advanced business environment. The complexity of supply chains, heightened by globalisation and cyber threats, necessitates a comprehensive approach to mitigate risks effectively.

Leveraging the PPRR Risk Management Model

The PPRR model stands as a robust framework in Supply Chain Risk Management, encompassing four key stages:

- Prevention: Implementing proactive measures to mitigate known supply chain risks.

- Preparedness: Developing detailed contingency plans to address potential disruptions.

- Response: Executing contingency plans efficiently to minimise the impact of disruptions.

- Recovery: Swiftly restoring supply chain operations to their normal capacity.

Managing Environmental Risks

The COVID-19 pandemic exemplified the critical need for environmental risk management in supply chains. Many businesses were compelled to reassess supplier relationships and adopt more resilient models, such as:

- Transitioning to Multi-sourcing: Diversifying suppliers to avoid over-reliance on a single source.

- Business Model Adaptation: Companies dynamically shifting production lines to meet emergent demands, thereby maintaining operational viability.

Supply Chain Risk Assessment Software

Utilising advanced software provides an edge in proactive risk management, allowing businesses to:

- Identify Weak Points: Pinpoint vulnerabilities within the supply chain.

- Data-Driven Insights: Harness data to strengthen supply chain resilience.

Improving Supply Chain Resiliency

Key strategies include:

- Multisourcing: Engaging multiple suppliers to circumvent potential disruptions.

- Nearshoring: Partnering with geographically closer suppliers to reduce lead times and inherent risks.

- Regular Stress Testing: Conducting periodic evaluations to identify hidden vulnerabilities.

- Buffering Inventory and Capacity: Maintaining additional inventory or capacity as a safeguard against supply chain disruptions.

- Product and Plant Harmonisation: Standardising components and technologies to ensure flexibility during disruptions.

Enhancing Cyber Supply Chain Risk Management

Given the critical role of digital technologies in supply chains, cybersecurity is paramount. Effective strategies include:

- Vendor Compliance Standards: Setting robust cybersecurity requirements for all third-party vendors.

- Vendor Risk Assessments: Thoroughly evaluating potential suppliers’ cybersecurity postures before partnership.

- Data Stewardship Standards: Clearly defining data ownership and usage policies.

- Unified Disaster Recovery Plans: Collaborating with vendors for cohesive cybersecurity strategies.

Supply Chain Visibility Improvement

Greater transparency in the supply chain can pre-empt many risks. This may involve:

- Technology for Product and Shipment Tracking: Utilising IoT sensors and real-time tracking systems for enhanced visibility.

- Freight Carrier Metric Tracking: Assessing carriers based on transit time, stop frequency, loading time, route optimisation, and maintenance schedules.

Implementing Logistics Contingency Plans

Creating contingency plans is vital for maintaining operations during unforeseen disruptions. Essential components include:

- Supply Chain Mapping: Understanding the entire supply chain to identify critical points.

- Supplier Network Diversification: Reducing reliance on single suppliers.

- Crisis Response Teams: Forming dedicated teams for emergency decision-making.

Risk Awareness Training

Building a risk-aware culture within the organisation through comprehensive training that covers:

- Common Supply Chain Risks: Educating employees about potential risks and best practices.

- Cybersecurity Protocols: Ensuring employees are trained in cyber hygiene and best practices.

Continuous Risk Monitoring

Constant vigilance is key in Supply Chain Risk Management. Automated digital solutions can provide real-time monitoring and alerts for potential risks.

Data-Driven Scenario Modeling

Leveraging Big Data, predictive analytics, and data modeling to forecast potential risk scenarios allows for more effective contingency planning.

Data Consolidation

Streamlining data storage into a centralised system enhances the ability to utilise data science and analytics effectively.

A multifaceted approach to Supply Chain Risk Management, incorporating advanced technologies, diversified strategies, and continuous improvement, is crucial for modern businesses. Such strategies not only help in mitigating risks but also enhance overall supply chain resilience, ensuring business continuity in the face of diverse and evolving challenges.

Challenges of Supply Chain Risk Management

Addressing the challenges of Supply Chain Risk Management (SCRM) is a multifaceted endeavour, essential for the effective and efficient operation of contemporary supply chains. Let’s delve deeper into each of these challenges:

- Complexity in Global Supply Chains:

- In an increasingly globalised world, supply chains span multiple countries and continents, intertwining various legal, cultural, and economic systems. This global network, while advantageous for business expansion and cost reduction, also introduces complexities. These include diverse regulatory requirements, political instabilities, and varied logistical challenges. Effectively managing these complexities requires an in-depth understanding of international trade dynamics and the ability to navigate different regulatory landscapes.

- Data Management and Quality:

- The success of Supply Chain Risk Management heavily relies on the quality and timeliness of data. Accurate, real-time data is crucial for making informed decisions and anticipating potential disruptions. However, collecting, processing, and analysing vast amounts of data pose significant challenges, especially in ensuring data integrity and security. The challenge is not only to gather this data but also to interpret it effectively for meaningful insights.

- Changing Risk Landscape:

- The risk landscape is constantly evolving, with new threats emerging regularly. Cybersecurity threats, for instance, pose a significant risk to digital infrastructure in supply chains. Climate change also introduces new environmental risks, affecting sourcing, production, and logistics. Adapting to these changes requires agility and a proactive approach in risk management, as well as staying abreast of emerging trends and technological advancements.

- Resource Allocation:

- Implementing effective Supply Chain Risk Management strategies often requires significant investment in terms of time, finances, and human resources. Organisations must balance these investments with other business priorities. The challenge lies in convincing stakeholders of the long-term value of SCRM, securing adequate resources, and optimally allocating them for maximum risk mitigation impact.

- Collaboration and Communication:

- Effective Supply Chain Risk Management necessitates collaboration and communication across various departments within an organisation and with external entities such as suppliers, logistics providers, and customers. However, creating a collaborative environment can be challenging, especially when dealing with external partners who have their own priorities and systems. Ensuring seamless communication, shared objectives, and aligned risk management strategies among all parties is crucial yet often difficult to achieve.

- Skill and Knowledge Requirements:

- The field of Supply Chain Risk Management is dynamic, requiring continuous learning and adaptation. Professionals in this field must keep up with the latest developments in risk management strategies, technological tools, and global supply chain trends. This requires ongoing training and development, which can be challenging, particularly in finding and retaining talent with the necessary skills and expertise.

Addressing these challenges is key to building a robust, resilient, and efficient supply chain, capable of withstanding various risks and disruptions. It requires a comprehensive approach, incorporating advanced technologies, strategic planning, and a culture of continuous improvement and collaboration.

How is supply chain risk management related to sustainability?

Supply Chain Risk Management (SCRM) is intrinsically connected to the pursuit of sustainability within business operations. In an era where environmental and social governance (ESG) is increasingly at the forefront of corporate strategy, SCRM plays a pivotal role in embedding sustainability into the supply chain.

Environmental Impact and Sustainability: Supply Chain Risk Management aids organisations in proactively identifying and mitigating environmental risks in their supply chains. This involves managing and reducing emissions, energy usage, and waste, thereby contributing significantly to the company’s overall environmental responsibility. Implementing technologies for tracking energy usage, for example, can lead to more energy-efficient operations and substantial reductions in carbon footprint. Moreover, SCRM supports the adoption of greener practices in sourcing materials and selecting environmentally responsible suppliers, fostering a supply chain that is both efficient and ecologically sustainable.

Promoting Circular Economy Principles: A key facet of sustainable Supply Chain Risk Management is its alignment with circular economy concepts, which aim to eliminate waste and continuously use resources. By thoroughly assessing risks, companies can make more informed decisions that reduce waste generation. For instance, a robust Supply Chain Risk Management framework might include strategies for recycling materials or re-routing supplies to avoid wastage, ultimately leading to more sustainable, closed-loop systems within the supply chain.

Contingency Planning for Sustainability: Effective Supply Chain Risk Management involves developing contingency plans to prepare for and respond to disruptions, ensuring the continuity of sustainable practices even under unexpected circumstances. This preparedness is crucial for maintaining the integrity of sustainability initiatives in the face of challenges, such as natural disasters or market volatility. By being equipped with well-thought-out contingency plans, businesses can continue their sustainable operations seamlessly, avoiding scenarios that might lead to increased waste or environmental damage.

Corporate Responsibility and Reputation: A thorough and effective Supply Chain Risk Management programme enhances a company’s standing as a socially responsible entity. In today’s market, consumers and stakeholders place high value on corporate responsibility, particularly in environmental and social domains. Companies that successfully integrate sustainability into their supply chain risk management can bolster their brand image and reputation, distinguishing themselves as leaders in corporate responsibility.

Aligning with Global Sustainability Goals: Incorporating sustainability into Supply Chain Risk Management aligns with global objectives, such as the United Nations Sustainable Development Goals (SDGs). By managing ESG risks, companies contribute to broader global efforts to promote sustainable economic growth, responsible consumption, and climate action. This alignment not only demonstrates a commitment to global initiatives but also ensures long-term business viability.

The integration of Supply Chain Risk Management and sustainability is not just a strategic alignment; it is a necessity for modern businesses. It signifies a commitment to ethical practices, environmental stewardship, and social responsibility, which are increasingly becoming benchmarks for corporate success and resilience. In this light, SCRM emerges not only as a tool for risk mitigation but as a catalyst for sustainable transformation within the global business landscape.

Reducing supply chain risk

Reducing supply chain risk involves a multi-faceted approach that encompasses various strategies and practices. These are designed to identify, assess, and mitigate potential risks, thereby enhancing the resilience and reliability of the supply chain. Key strategies include:

- Diversification of Suppliers: Reducing reliance on a single supplier or geographic region can mitigate risks associated with supply disruptions. Establishing relationships with multiple suppliers ensures alternative sources are available if one faces challenges.

- Enhanced Quality Control: Implementing stringent quality control measures at various stages of the supply chain helps in early detection of issues, preventing the escalation of problems that could disrupt the supply chain.

- Demand Forecasting and Inventory Management: Accurate forecasting and effective inventory management enable businesses to balance supply and demand efficiently, reducing risks related to stockouts or overstocking.

- Robust Risk Assessment and Monitoring: Regularly assessing potential risks and continuously monitoring the supply chain for emerging threats helps in proactive risk management. This involves keeping abreast of market trends, geopolitical developments, and other external factors that could impact the supply chain.

- Investment in Technology: Leveraging advanced technologies such as blockchain, IoT, and AI for better visibility and tracking throughout the supply chain. These technologies can enhance data accuracy, provide real-time monitoring, and improve decision-making processes.

- Establishing Strong Relationships with Key Stakeholders: Building solid partnerships with suppliers, logistics providers, and customers facilitates better communication and collaboration, essential for managing risks effectively.

- Flexible and Agile Operations: Developing an adaptable supply chain that can quickly respond to changes and disruptions. This includes having contingency plans in place for rapid adjustments in operations, such as rerouting shipments or altering production schedules.

- Compliance with Regulatory Standards: Ensuring adherence to international and local regulatory standards minimises legal and financial risks associated with non-compliance.

- Training and Development: Investing in employee training to enhance skills in risk identification, assessment, and mitigation. A well-trained workforce is better equipped to handle supply chain challenges.

- Sustainability Practices: Incorporating sustainable practices into the supply chain reduces environmental risks and aligns with evolving regulatory and consumer expectations.

- Insurance and Financial Risk Management: Utilising insurance and financial tools to protect against losses from supply chain disruptions, including trade credit insurance, can provide a financial buffer.

By implementing these strategies, businesses can significantly reduce their supply chain risks, ensuring smoother operations, maintaining customer satisfaction, and ultimately achieving greater business resilience.

Supply chain resilience options

To build resilience in supply chains, several strategic options can be employed. These options focus on creating a supply chain capable of withstanding various disruptions and quickly recovering from any that occur. Key options include:

- Building Redundancy into the Supply Chain:

- Redundancy involves creating backup options in the supply chain to ensure continuity in case of disruptions. This might include additional production facilities, backup suppliers, or extra inventory. While redundancy can increase costs, it significantly reduces the risk of complete shutdowns due to unforeseen events.

- Diversifying Supplier Networks:

- Diversification of the supplier base reduces dependence on any single supplier or region. By sourcing materials or components from a variety of suppliers located in different geographic areas, businesses can mitigate the risk of disruptions due to localised events like natural disasters, political instability, or supplier-specific problems.

- Investing in Technology and Infrastructure:

- Technology plays a crucial role in enhancing supply chain resilience. Investment in advanced technologies like blockchain for traceability, IoT for real-time monitoring, and AI for predictive analytics can provide greater visibility and agility in the supply chain. Robust IT infrastructure, including cloud computing, ensures data accessibility and continuity in operations.

- Collaborating with Key Stakeholders for Resilience Enhancement:

- Collaborative relationships with suppliers, customers, logistics providers, and other stakeholders are vital. This involves sharing information, joint risk assessment, and collaborative planning for disruptions. Collaboration can lead to shared solutions that enhance the resilience of the entire supply chain network.

Building resilience in the supply chain is about preparing for, responding to, and recovering from disruptions effectively. It involves a balance of strategic planning, investment in technology, and fostering strong relationships with all supply chain participants. By adopting these resilience options, companies can ensure their supply chains are robust, flexible, and capable of withstanding various challenges.

Ready to Elevate Your Supply Chain Risk Management Program?

Supply chain risk management involves tasks such as managing due diligence, conducting supplier assessments, assigning vendor criticality ratings, performing SCRM risk assessments, nurturing vendor relationships, and conducting periodic supplier reviews. Additionally, collaborating with various stakeholders within the company to ensure that risk mitigation activities are being executed adds another layer of complexity.

However, there’s a solution to streamline these processes: implementing a robust risk management software solution.

Centralise your Supply Chain Risk Management programme, streamline stakeholder communications, and effectively manage key information. Embrace technology to optimise your supply chain risk management strategy and enhance your organisation’s resilience against potential disruptions.

How can Neotas Third Party Vendor Due Diligence solutions help?

Neotas offers an innovative solution to businesses grappling with Third-Party Risk Management (TPRM). In an era of increasing outsourcing, TPRM has become pivotal, and Neotas recognises this need. Through our enhanced due diligence platform, businesses can efficiently track and evaluate vendors and contractors, ensuring adherence to security protocols in a cost-effective manner.

The Neotas platform automates the vendor onboarding process, streamlining the addition of new vendors with remarkable ease and speed.

Moreover, Neotas provides a customisable dashboard, enabling businesses to proactively identify and address emerging risks. By consolidating vital vendor information, Neotas facilitates the seamless integration of risk management into existing Customer Relationship Management (CRM) and Supply Chain Management (SCM) systems, ultimately helping businesses maximise profits while minimising risk exposure.

Request a Demo

If you’re curious about whether our Third-Party Risk Management and Third-Party Vendor Due Diligence solutions align with your organisation, don’t hesitate to schedule a call. We’re here to help you make informed decisions tailored to your needs.

Frequently Asked Questions

What is Supply Chain Risk Management?

Supply Chain Risk Management (SCRM) involves proactively identifying, assessing, and mitigating risks that could disrupt or hinder a supply chain’s operations. It’s an integral part of logistics planning, ensuring the smooth flow of goods, services, and information from suppliers to customers. SCRM encompasses strategies to address potential disruptions due to various factors like supplier reliability, logistics issues, market changes, environmental impacts, and geopolitical shifts, aiming to maintain continuity and efficiency in the supply chain.

Why is Supply Chain Risk Management Important?

SCRM is vital because it protects businesses from unexpected disruptions that can cause significant financial losses, damage to reputation, and operational setbacks. It enhances supply chain resilience, ensuring that companies can continue to meet customer demands and maintain market competitiveness despite unforeseen challenges. Effective SCRM supports business continuity, sustains customer trust, and helps in managing the increasingly complex nature of modern global supply chains.

How Can We Assess Supply Chain Risks?

Assessing supply chain risks involves a thorough analysis of the entire supply chain network. This includes identifying potential risk factors at each stage of the supply chain, evaluating the likelihood and impact of these risks, and continuously monitoring for new or evolving threats. Tools such as risk assessment matrices, software applications, and data analytics are often employed to systematically identify and quantify risks, providing a basis for developing mitigation strategies.

What Strategies Can We Use to Mitigate Supply Chain Risks?

Strategies to mitigate supply chain risks include diversifying suppliers to avoid over-reliance on a single source, investing in robust logistics and information technology systems, and developing comprehensive contingency plans for potential disruptions. Regular training of staff on risk awareness, collaborative risk management with supply chain partners, and maintaining optimal inventory levels to cushion against demand fluctuations are also effective strategies.

What is Technology’s Role in Supply Chain Risk Management?

Technology plays a critical role in SCRM by providing tools for better visibility, monitoring, and predictive analytics in the supply chain. Innovations such as the Internet of Things (IoT), Artificial Intelligence (AI), blockchain, and cloud computing enable real-time tracking, enhance data accuracy, and facilitate rapid response to disruptions. Technology aids in risk identification, analysis, and the implementation of proactive measures to mitigate potential impacts.

What is the Difference Between Supply Chain Risk and Third-Party Risk?

Supply chain risk encompasses the potential disruptions in the end-to-end process of manufacturing and distributing products, which includes a variety of factors such as production issues, logistics, market demand, and external events. Third-party risk, on the other hand, specifically refers to the risks associated with relying on external partners or suppliers, focusing on the challenges and uncertainties that come from dependencies on these external entities.

What are the 4 Types of Risk in Supply Chain Management?

- Operational Risks: Involving internal processes, such as production inefficiencies, equipment failures, and human errors.

- Geopolitical Risks: Associated with political instability, trade conflicts, and regulatory changes in countries involved in the supply chain.

- Market Risks: Related to demand volatility, price fluctuations, and changing customer preferences.

- Environmental and Natural Disaster Risks: Due to events like earthquakes, floods, and climate change impacting supply chain operations.

What are the 5 Key Steps in Managing Supply Chain Risk?

- Risk Identification: Spotting potential sources of supply chain disruption.

- Risk Assessment: Evaluating the likelihood and potential impact of identified risks.

- Strategy Development: Formulating strategies to mitigate or manage risks.

- Implementation: Executing the developed risk management strategies.

- Monitoring and Review: Continuously tracking risk factors and adjusting strategies accordingly.

What are the 5 Sources of Supply Chain Risk?

- Supplier Risk: Challenges arising from supplier performance or instability.

- Logistical Risk: Issues related to transportation, warehousing, and handling.

- Technological Risk: Cybersecurity threats and technological failures.

- Environmental Risk: Impacts of natural disasters and climate change.

- Political and Regulatory Risk: Effects of political instability and changes in laws or regulations.

Why is Supply Chain a Risk?

The supply chain is inherently risky due to its complex network of interconnected processes and dependencies. It is susceptible to various internal and external factors that can cause disruptions, such as supplier failures, logistical challenges, market shifts, and external events like natural disasters or political changes. These risks can impact the efficiency, cost-effectiveness, and reliability of the supply chain, making its management crucial for business success.

What is Supply Chain in Simple Words?

A supply chain is a network of steps involving the production, handling, and distribution of goods or services, starting from the procurement of raw materials to the delivery of the final product to the consumer. It encompasses various processes and entities working together to efficiently move a product from the supplier to the customer.

What are the 3 Main Types of Risk?

- Strategic Risk: Risks related to business decisions and market position.

- Operational Risk: Risks arising from day-to-day business activities.

- Financial Risk: Risks related to financial operations and market conditions.

What is the Biggest Risk in Logistics?

The biggest risk in logistics often includes transportation disruptions, which can arise from a variety of sources such as vehicle breakdowns, traffic issues, infrastructural challenges, and external events like strikes or natural disasters, leading to delays and increased costs.

What is Logistics Risk?

Logistics risk refers to potential disruptions or inefficiencies in the movement, storage, and handling of goods. It includes risks related to transportation delays, warehousing challenges, inventory management, and handling errors, which can affect the timeliness and reliability of delivering products.

What are the 7 R’s of Supply Chain Management?

- Right Product: Ensuring the correct product is delivered.

- Right Quantity: Delivering the appropriate quantity ordered.

- Right Condition: Ensuring the product is in good condition.

- Right Place: Delivering to the correct location.

- Right Time: Ensuring timely delivery.

- Right Customer: Delivering to the intended customer.

- Right Cost: Managing costs effectively throughout the supply chain.

How Do You Identify Supply Chain Risk?

Identifying supply chain risk involves analysing the entire supply chain process, from sourcing to delivery. This includes reviewing supplier stability, assessing transportation and logistical networks, monitoring market trends, evaluating regulatory compliance, and considering potential environmental impacts. Tools like risk matrices, software applications, and stakeholder feedback are commonly used.

How to Manage Supply Chain?

Managing a supply chain involves coordinating and optimising the flow of products, information, and finances from origin to consumption. This includes efficient procurement, production scheduling, inventory management, quality control, logistics planning, and customer service. It requires strategic planning, technological integration, and collaboration with all supply chain stakeholders.

What is the Last Step of Supply Chain Risk Management?

The last step in supply chain risk management is continuous monitoring and review. This involves regularly assessing the effectiveness of implemented strategies, adapting to new or changing risks, and refining the risk management process based on new information and insights.

What is the First Step of Supply Chain Risk Management?

The first step in supply chain risk management is risk identification, which involves recognising potential risks that could impact the supply chain. This can be achieved through analysis of historical data, market research, stakeholder input, and monitoring of external environmental factors.

What Type of Risk is Supply Chain?

Supply chain risk is a composite risk encompassing various aspects like operational, financial, strategic, and reputational risks. It is derived from the uncertainties and potential negative impacts associated with the global network of suppliers, manufacturers, logistics, and customers in a supply chain.

What are the Four Main Elements of a Supply Chain?

- Procurement: Sourcing raw materials and services required for production.

- Production: Converting raw materials into finished products.

- Distribution: Transporting and distributing products to customers.

- Integration: Ensuring all elements of the supply chain work together efficiently.

What are the Five Types of Supply Chain Management?

- The Lean Supply Chain: Focuses on efficiency by eliminating waste.

- The Agile Supply Chain: Emphasises flexibility and quick responses to market changes.

- The Responsive Supply Chain: Aims to respond rapidly to customer demands.

- The Green Supply Chain: Prioritises environmentally sustainable practices.

- The Global Supply Chain: Manages operations on a global scale, dealing with international suppliers and customers.

Related Case Studies:

- Third Party Risk Management (TPRM) Using OSINT

- Open-source Intelligence For Supply Chain – OSINT

- ESG Risk Management Framework with Neotas’ OSINT Integration

- Open Source Intelligence In AML Compliance | Case Study

- Identifying Difficult And Dangerous Senior Managers

- ESG Risk Investigation Uncovers Supply Chain Risks

- Financial Crime Compliance & Risk Management Trends

- Network Analysis Reveals International Links In Credit Risk Case

- Network Analysis and Due Diligence – Terrorist Financing

- Using OSINT For Sources Of Wealth Checks

- ESG Risks Uncovered In Investigation For Global Private …

- PEP Screening: Undisclosed Political Links Uncovered For European Organisation

New Whitepaper and Checklist

New Whitepaper and Checklist